Questions Regarding Your Display?

Contact us and we will

connect you to a technician

who will assist you.

In today's fast-changing environment, it's becoming more and more difficult for many companies to find replacement display monitors for their costly industrial equipment. Often, the CRT monitor originally installed in an older CNC machine tool or industrial lathe control has become obsolete and is no longer supported by the original manufacturer. In some cases, the original monitor manufacturer may even be out of business. In today's market, repairing a failed CRT display may be impossible, and replacements can be costly and hard (if not impossible) to come by. Indeed, most modern LCD monitors simply will not function properly when used to replace a CRT monitor in a legacy control system. To make matters worse, most monitor manufacturers don't want to be 'bothered' with supporting legacy systems that are not their own, and even if they agree to look at your problem, they are often very expensive.

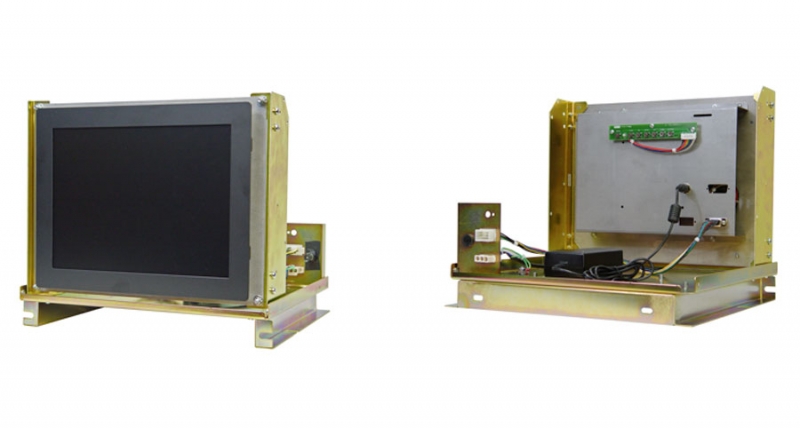

Dynamic Displays can help you find an affordable solution to replace your display monitor. For years, we have specialized in modifying our LCD display monitors to meet our customer's legacy monitor needs. We now provide affordable drop-in replacement LCD monitors for a wide variety of industrial legacy computer monitor applications that require special timing or unique packaging, and the list keeps growing.

Often the problem is inherent in the design of these older systems. Prior to the founding of the Video Electronics Standards Association (VESA) 1989, there were no international standards for computer-generated signals. Consequently, a myriad of various signal formats and interface configurations proliferated throughout the industrial control community. These ranged from:

• Three-wire analog video formats, where the horizontal and vertical synchronization signals are embedded within the green video input signal. These are generally indicated when a color display has only three coaxial input connectors. A number of methods were used to encode these synchronization signals (RS-170/343 with and without serrations and equalizing pulses, ORed or X-ORed) each of which presents its own unique challenge to modern LCD display systems.

• Four-wire analog video formats, where the horizontal and vertical synchronization signals are embedded within a separate composite sync signal. These are generally indicated when a color display has only four coaxial input connectors. Like three-wire systems, a number of methods were used to encode these synchronization signals, each of which presents its own unique challenge to modern LCD display systems.

• Five-wire analog video formats, where the horizontal and vertical synchronization signals are provided on separate signal lines.

• Interlaced video, where half the image is presented in each consecutive vertical field and interleaved to recreate the video image. This encoding was often used on three, four, and five-wire systems to reduce the frequencies required to send an image.

• Digital video, such as CGA, EGA, or MDA, where the video information is presented in 1 or 2 bits per color. This was sent via single or differential TTL or ECL transmission lines.

• NTSC/PAL/SECAM video – the three predominant television standards, where all video information arrives on a single line.

Our QES1500 series Industrial LCD monitors is compatible with most three, four and five-wire analog video formats found in legacy systems. In addition to the modern IBM and VESA-inspired VGA, SVGA and XGA display formats, our rugged LCD displays also can be configured to work with a variety of the older, non-standard video timings, including MDA, CGA and EGA digital formats, RS170 and RS343 analog video-type formats, and many others. We have developed solutions for displays requiring ECL and TTL RS422-type differential transmission line inputs for monitors used in noisy, shop-floor environments. We have customized our monitors to work with ABB, Westinghouse, Fisher, Bailey, Allen-Bradley, Foxboro, Honeywell, Moore, Siemens, Forney, Harris, Fanuc timings & many other video formats.

To find a suitable replacement LCD monitor, please click the following link to our latest cross-reference listing of new LCD replacements for your old CRT monitors. There you can search by OEM system or CRT manufacture's model number for the appropriate LCD replacement.

If you are having trouble sourcing a video display for an older Allen Bradley 8400MP Control Machine (Toshiba D12CX73), a Fanuc CNC A61L-0001-0074 & A61L-0001-0094 Monitor, or a Mazak 14" Replacement Monitor C-3470, C-5470, 8DSP40, 26S-14O19L, CD1472-D1M monitor, our engineering staff will be happy to customize a rugged LCD display to meet the unique computer monitor specifications required and extend the life of your production equipment. If we don't have a standard replacement LCD display for your particular CRT monitor model, we'll be glad to work with you to arrive at a cost-effective solution. Often, all that is necessary is that you provide us with basic pin-out and/or timing information and mounting information and we'll do the rest. It may be possible for you to send us your old monitor chassis or enclosure and we'll install our electronics, or design a chassis that will mount in the same location as the original CRT monitor. Occasionally, more information may be required, but we'll be happy to work with you.

In any case, if you have a unique display monitor application that cannot be met elsewhere, give us a call. We'll be glad to help.

Contact us. We can provide you with Display Solutions for your legacy monitor needs.

Contact us and we will

connect you to a technician

who will assist you.

Para nestros clientes de habla hispana tenemos el numero 800-792-6862 para ofrecerles nuestros servicios de venta y accesoria técnica.

Industrial Panels offers a new line

of industrial LCD replacements for outdated CRT displays used in many OEM systems.